Automated truck loading system for imported commodities

Dry Cargo International magazine

Engineering and equipment

“We are seeking a mobile hopper solution that can deliver on safety, mobility, product handling capacity as well as flexibility and reliability in a tough marine operating environment.”

This was the simple brief from one of Kilic Engineering’s (KE’s) Australian customers when it went to market seeking an improved solution to its ship-unloading operations across eight different commodities that were being unloaded by a grab, dropped onto the wharf and then loaded to trucks using a front-end loader.

The customer along with its consulting engineer conceptualized a machine that would receive material from the ship via the grab and automatically fill trucks as they indexed through a loading lane on the wharf. It was a clever concept and one that the KE engineering team immediately embraced, and challenged, as the team leveraged its material handling experience and gained a better understanding of the commodities the customer anticipated unloading.

“An automated unloading machine that would handle mineral products as well as scrap steel was a challenge that KE was excited to take on,” said Jason Kilic, KE’s managing director. “Visiting our customer, getting physically close to and inspecting the commodities and reviewing the work and experience KE had with similar materials in the past were all essential in arriving at a design that both honoured the customer’s concept and incorporated mechanical features that ultimately made it work.

“Our team has been delivering material handling technology across diverse industrial sectors since the company was started by Tony Kilic in 1975. It has been thoroughly rewarding to find that our knowhow can add value to port operations, a part of the supply chain which KE has only recently engaged in,” Kilic added.

And add value it did. With two of these machines now delivered, the customer has started to see the benefits of a machine that recognizes trucks and automatically loads them with the correct weight of material. The grab is able to unload continuously, filling a large semi-trailer mounted hopper that then, through a system of conveyors and load cells, dispenses material to each truck in the loading lane.

“The result we achieved was testament to KE’s commitment to building relationships as we collaborated with our customer, its engineer, Southern Cross Trailers and Tristar Electrical to achieve the required material handling capability, machine mobility and automation. “It was an exciting dynamic as we presented ideas, challenged each other, debated the application and ultimately delivered a machine that made the concept a reality,” Kilic said.

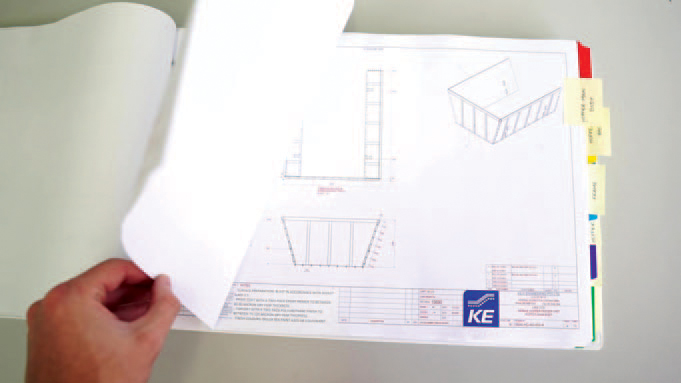

The machine was designed, manufactured, fully assembled and then fully tested with material in South Australia before being shipped to its east-coast port destination.

“We worked hard to test everything we could before delivering the first machine and this gave us and our customer confidence that both machines were ready for site operations. “I’d love to say that everything went smoothly and according to plan. The truth is there were a few unanticipated issues that emerged as the customer began to use the machine. This kept the KE team on its toes as it tweaked parts of the design an leveraged its in-house manufacturing capability to resolve issues and optimize the machine’s performance.

Winning business, designing a solution and manufacturing it from KE’s Australian manufacturing facility is just part of this great story. KE’s experience in working with local partners and a global supply chain has enabled it to tailor equipment to ensure there are local resources to leverage to assist KE’s interstate customers with any issues. More importantly, KE has quickly adapted to deliver customer support through a variety of channels.

The KE team are enjoying the challenges new markets are throwing at them and thriving on delivering novel, hard-working equipment solutions that enhance the safety, productivity and reliability of KE customer operations. Entrepreneurial port operators with a bold strategy for improvement and growth should contact KE to learn more about its capabilities for automated handling of commodity products.

ABOUT KILIC ENGINEERING

Kilic Engineering is a diverse mechanical engineering company based in Adelaide, South Australia, owned and operated by the Kilic family since 1973. The company has a long and proud history of excellence in designing, manufacturing and installing a very wide range of conveyors, material handling systems, structures and associated equipment. The company is grateful to and pleased to also acknowledge the contributions of its local suppliers including Tristar Electrical, Southern Cross Trailers and SEW Eurodrive.

Dry Cargo International, June 2023