Kilic Engineering turns expectations into reality

Australian Bulk Handling Review lastest news

Agriculture, Bulk Equipment, Latest News

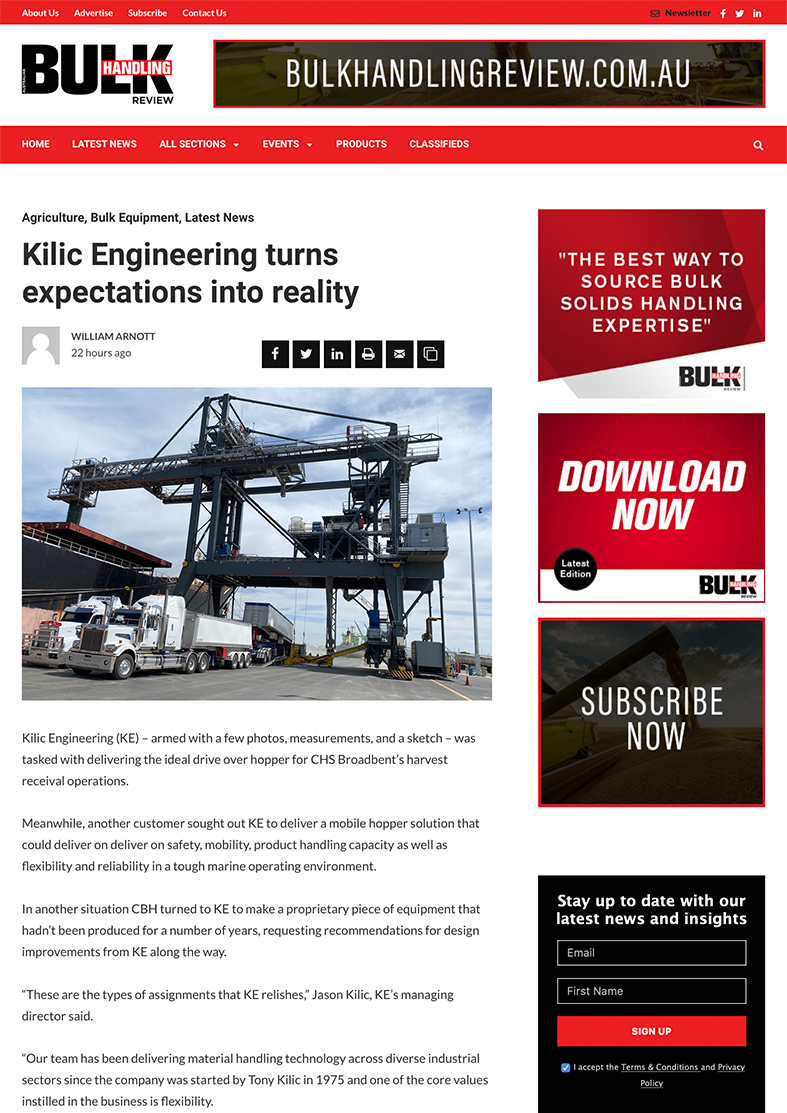

Kilic Engineering (KE) – armed with a few photos, measurements, and a sketch – was tasked with delivering the ideal drive over hopper for CHS Broadbent’s harvest receival operations. Meanwhile, another customer sought out KE to deliver a mobile hopper solution that could deliver on deliver on safety, mobility, product handling capacity as well as flexibility and reliability in a tough marine operating environment. In another situation CBH turned to KE to make a proprietary piece of equipment that hadn’t been produced for a number of years, requesting recommendations for design improvements from KE along the way. “These are the types of assignments that KE relishes,” Jason Kilic, KE’s managing director said. “Our team has been delivering material handling technology across diverse industrial sectors since the company was started by Tony Kilic in 1975 and one of the core values instilled in the business is flexibility.

.

“When challenged, we can count on our engineers, our manufacturing team and our long-established suppliers to switch into problem solving mode and collaborate on a solution,” Kilic said. An essential part of KE’s approach is to get close to the customers’ operations and understand the operational requirements as well as the physical characteristics and behaviour of the material being handled. With all three opportunities mentioned above, KE took the time to visit customer sites and gather data. “Visiting our customer, getting physically close to and inspecting the commodities and reviewing the work and experience KE has had with similar materials in the past are all essential in arriving at a design that honours the customer’s concept and incorporates features that ultimately make them add value,” Kilic said.

The KE response to all three challenges were machines that delivered against customer expectations and resulted in KE manufacturing multiple units. “The results achieved are testament to KE’s commitment to building relationships as we collaborated with our customers, KE sub-contractors and amongst our internal stakeholders to deliver the required material handling capability, machine mobility and automation. “These are exciting and dynamic assignments and KE is in its element as it presents ideas, challenges customer concepts, respects operational parameters and ultimately delivers equipment that makes ideas a reality,” Kilic said.

KE equipment is then thoroughly factory tested, with actual material if possible, before it is transported to customer sites across Australia. “We work hard to test everything we can before delivering machines and this gives us and our customer confidence that machines are ready for site operations,” he said. “I’d love to say everything goes smoothly and according to plan every time. The truth is, unanticipated issues emerged in all three cases as the customers began to use their machines. This keeps the KE team on its toes, tweaking aspects of design and leveraging in-house manufacturing capability to resolve issues and optimise machine performance. “Clearly KE is able to perform and support products across Australia. Our abilities and solutions were tested by our customers against other offerings in the market in all three situations and the KE solutions speaks for themselves. These challenges are great and it’s an exciting time.”

Winning business, designing a solution and manufacturing it from KE’s Australian manufacturing facility is just part of this great story. KE’s experience in working with local partners and a global supply chain has enabled it to tailor equipment to ensure there are local resources to leverage that assist KE’s interstate customers with any issues. More importantly, KE has quickly adapted to deliver customer support through a variety of channels. The KE team are enjoying the challenges new customers and markets are throwing at them and thriving on delivering novel, hard-working equipment solutions that enhance the safety, productivity and reliability of KE customer operations.

William Arnott

Australian Bulk Handling Review, June 2023

Related stories:

Kilic Engineering delivers the goods for CBH harvest

Reaping the benefits with SEW Eurodrive and Kilic Engineering

Kilic and Kinder grow together