Kilic Engineering designs underbelly for its Roo

Australian Bulk Handling Review lastest news

Agriculture

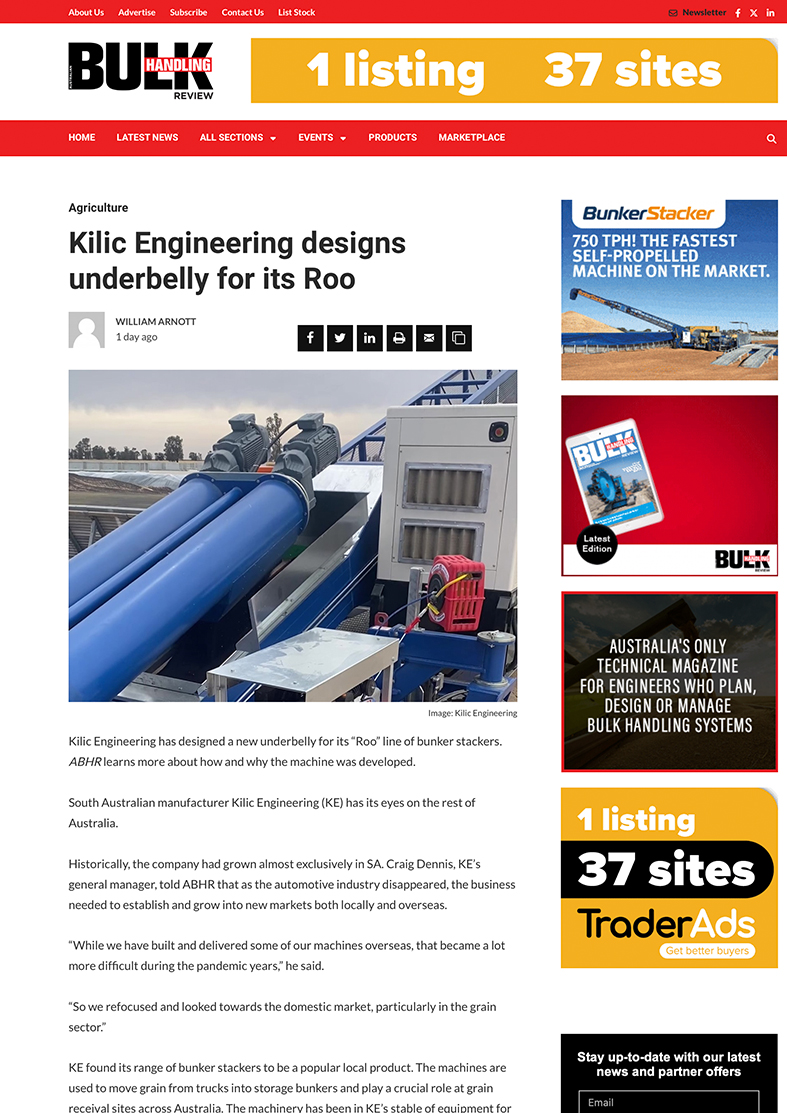

Kilic Engineering has designed a new underbelly for its “Roo” line of bunker stackers. ABHR learns more about how and why the machine was developed.

South Australian manufacturer Kilic Engineering (KE) has its eyes on the rest of Australia. Historically, the company had grown almost exclusively in SA. Craig Dennis, KE’s general manager, told ABHR that as the automotive industry disappeared, the business needed to establish and grow into new markets both locally and overseas.

“While we have built and delivered some of our machines overseas, that became a lot more difficult during the pandemic years,” he said. “So we refocused and looked towards the domestic market, particularly in the grain sector.”

KE found its range of bunker stackers to be a popular local product. The machines are used to move grain from trucks into storage bunkers and play a crucial role at grain receival sites across Australia. The machinery has been in KE’s stable of equipment for almost two decades now, changing a lot during that time in response to customer demands for faster and safer equipment for their grain operations.

In 2023, one customer had a specific request. They were handling canola, which can be quite oily, and had started using an auger to deal with the product. That way, if it caked up, the motion of the auger would clean itself. The customer approached KE and asked if it would be possible to include an auger as part of the bunker stacker machinery, instead of the underbelly belt conveyor that has long been part of the success of the bunker stacker range.

Dennis said KE was committed to working with them and set about designing a machine that could take material from a truck and deliver it onto the main conveyor. “We had confidence in our design team to make it work, and there was a lot of enthusiasm from the customer,” he said. “From design to completion, the process took about six months – something the team is really proud of. “After seeing the first one work so well, we let other Roo customers know. We built a total of four throughout 2023, each version incrementally improving on the design.”

The lucky few that have had early access to the machine have appreciated the machine during last year’s busy harvest season. They have been able to switch it from canola to wheat and other cereals with no issue. There were even situations where truck drivers delivering the grain asked to use the KE machines, as they were much faster than the others on site. Feedback plays an important part in KE’s design process. Dennis said that while the word is a bit cliché these days, “collaboration” was the key.

“It’s a good word to describe what happened. We spent time at our customers’ sites and invited them to our workshop. We learned about what worked and what didn’t from them,” he said. “As the same time we worked with our own suppliers to understand what we could do to put a machine like this together. “The big challenge was finding the space on the machine to fit the underbelly auger and all of the additional equipment to support it. Our bunker stackers only need one motor to drive them, but the auger would require six.”

In addition, KE also brought in its tradespeople, especially its fitters, to learn how hard it would be to build and to find the right materials to use, and how long it would take. Everything from the auger itself to the bearings and other mechanical components were lined up to ensure it would all work correctly. Dennis said the company strives to create a culture of open communication and connection with its customers.

“We build genuine relationships with not only the senior people, but also the people operating the equipment,” he said. “We take their feedback on board, becoming more attuned to what they are looking for in a machine. “It’s also not just myself and Jason Kilic, our managing director. We make sure the people on our factory floor who built the machines have an opportunity to get up close with it.”

While the new machine doesn’t have a name just yet, Kilic Engineering plans to launch the underbelly auger bunker stacker in 2024. The company has delivered machines from coast to coast and plans to continue with its strategy of national expansion. Dennis said it’s a busy time at the moment, as KE begins planning for the year ahead. “We’re working through a review of everything we did in 2023, looking internally at things we can tune and improve,” he said. “Then we plan to visit our customers throughout the summer to inform our product development work. “KE will also be attending the Grain Elevator and Processing Society (GEAPS) annual conference and expo in the US. We’re looking forward to bringing Kilic Engineering’s bunker equipment to the US market and hope to sell several machines internationally while growing at home.”

William Arnott

Australian Bulk Handling Review, February 2024

Related stories:

Kilic Engineering turns expectations into reality

Kilic Engineering concludes development on Super Roo

Kilic Engineering delivers the goods for CBH harvest